KÖPRÜLER

- Karayolu köprüleri genel kitaplık.

- Design of Highway Bridges An LRFD Approach by Barker and Puckett, John Willey & Sons

- AASHTO, (American Association of State Highway and Transportation Officials) Amerika EyaletYolları ve Ulaşım Çalışanları Kurumu nun Köprüler ile alakalı dökümanları

- AASHTO LRFD Bridge Design Specifications - SI Units 4th Edition 2007

- Bridge Engineering Handbook

Bir köprü mühendisinin tasarım ve yapım örnekleriyle birlikte başucu kitabı.

Yazarlar : Wai-Fah Chen and Lian Duan

İçindekiler;

- Precast – Pretensioned Concrete Girder Bridges

- Cast-in-Place Posttensioned Prestressed Concrete Girder Bridges

- Composite Steel I-Girder Bridges

- Composite Steel Box Girder Bridges

- Horizontally Curved Girder Bridges

- Highway Truss Bridges

- Arch Bridges

- Suspension Bridges

- Cable-Stayed Bridges

- Extradosed Bridges

- Stress Ribbon Pedestrian Bridges

- Movable Bridges

- Floating Bridges

- Concrete Decks

- Orthotropic Steel Decks

- Approach Slabs

- Expansion Joints

- Railings

- Foundation Design&Construction

Yazar : M J TOMLINSON

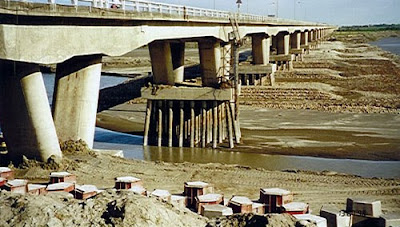

Köprü ayaklarında suyun oyma etkisi dikkate alınmış mı ???

- Köprü ayaklarında suyun oyma etkisi (Scour at the bridge piers)

Bu konu ile alakalı; İTÜ iki adet tez, İMO bir adet bildiriyi aşağıdaki linkden sıkıştırılmış olarak indirebilirsiniz.

ÖNGERME

- Öngermeli Hazır Betonarme Kiriş İmalatı Resimli Anlatım

indirme linki - Öngermeli Hazır Betonarme Kiriş İmalatı Resimli Anlatım

GERGİN EĞİK KABLO ASKILI KÖPRÜLER (CABLE - STAYED BRIDGES)

- Configuration(General Layout • Cables • Girder • Tower)- Design (Permanent Load Condition • Live Load • Thermal Loads • Dynamic Loads)- Superlong Spans- Multispan Cable-Stayed Bridges- Aesthetic Lighting- Summary

indirme linki - Gergin Eğik Kablo Askılı Köprüler (Cable - Stayed Bridges)

indirme linki - Movable Scaffolding System - Underslung Solution

Overhead MSS ait örnek resimler :

GERGİN EĞİK KABLO ASKILI KÖPRÜLER (CABLE - STAYED BRIDGES)

- Gergin Eğik Kablo Askılı Köprüler (Cable - Stayed Bridges) ile alakali tüm teknik bilgiler. Bridge Engineering Handbook - Yazarlar Wai-Fah Chen and Lian Duan - Bölüm 19 - "Cable-Stayed Bridges"

- Configuration(General Layout • Cables • Girder • Tower)- Design (Permanent Load Condition • Live Load • Thermal Loads • Dynamic Loads)- Superlong Spans- Multispan Cable-Stayed Bridges- Aesthetic Lighting- Summary

indirme linki - Gergin Eğik Kablo Askılı Köprüler (Cable - Stayed Bridges)

Movable Scaffolding System - MSS ( hareketli iskele sistemi)

Movable Scaffolding System - MSS (hareketli iskele sistemi) karayolu köprüleri ve demir yolu köprüleri için tip kesit olarak single T, double T, single box, double box kesitlerinde köprü inşaatı için bir yapım metodudur. Norveçli mühendisler tarafından geliştirilmiştir ve Strukturas isimli firma tarafından ilk kez uygulanmıştır ve Strukturas tarafından 200'den fazla projede uygulanmıştır. Yerinde dökme (cast-in-situ) köprüler için iş gücü maliyetinin düşük olması, yapım süresinin kısalması, kapalı bir sistem olmasından ötürü yüksekte çalışan işçiler için iş güvenliği özellikleri ile ön plana çıkmaktadır. açıklık olarak 20 mt ile 70 mt arasında uygulanmaktadır. Türkiyede Ankara - Sivas arası Yüksek Hızlı Tren hattı projesinde Kırıkkale'deki viyadük inşaatında 40 metre ve 90 metre açıklık ile uygulanmaktadır, 90 metre açıklık ile Dünya'da ilk defa Türkiyede uygulanmaktadır. Yatay kurp yarıçapı minumum 250 metre ve üstü olan olan güzergahlarda uygulanabilmektedir. Sistem, kendi askı sistemi ile çalışmakta ve açıklıklar arasındaki tabliyelere döküm tek seferde uygulanmaktadır. Sistem kenar ayak üzerinde kuruluyor ve montaj ediliyor. Sonrasında ise ilk açıklıktaki betonu döküyor ve ilerliyor.

İki farklı tipi mevcuttur.

1 - Underslung MSS (sistem tabliyenin altında)

2 - Overhead MSS ( sistem tabliyenin üstünde)

İki farklı tipi mevcuttur.

1 - Underslung MSS (sistem tabliyenin altında)

2 - Overhead MSS ( sistem tabliyenin üstünde)

Underslung MSS ait örnek resimler :

indirme linki - Movable Scaffolding System - Underslung Solution

Overhead MSS ait örnek resimler :

indirme linki - Movable Scaffolding System - Overhead Solution

EKSTRA DOZ KÖPRÜLER ( EXTRADOSED BRIDGES)

Ekstra Doz Köprü nedir?

Nerelerde Uygulanmalıdır?

Ekstra doz köprünün karakteristik özellikleri,

Ekstra doz köprünün avantajları,

Ekstra doz köprünün kısımları,

Ekstra doz köprü tasarımı,

Ekstra doz köprünün yapısal elemanlarının detayları,

Ekstra doz köprü yapım yöntemi,

Örnek olay incelemesi,

Genel ekstra doz köprü fotoğraları

indirme linki - Ekstra Doz Köprüler - Extradosed Bridges

Nerelerde Uygulanmalıdır?

Ekstra doz köprünün karakteristik özellikleri,

Ekstra doz köprünün avantajları,

Ekstra doz köprünün kısımları,

Ekstra doz köprü tasarımı,

Ekstra doz köprünün yapısal elemanlarının detayları,

Ekstra doz köprü yapım yöntemi,

Örnek olay incelemesi,

Genel ekstra doz köprü fotoğraları

indirme linki - Ekstra Doz Köprüler - Extradosed Bridges

Tacoma Narrows Köprüsünün Göçme Nedenleri (Understanding Tacoma Narrows Bridge Collapse)

Köprü Mühendisliği tarihinde kayıtlara geçen en büyük asma köprü göçmesi örneği Tacoma Narrows asma köprüsü (Galloping Gertie). Temmuz 1940 yılında servise açılmış ve açılıştan dört ay sonra aynı yıl içinde göçmüştür. Bu felaket köprü inşaatında aerodinamik araştırmaların öneminin artmasına ve köprü inşaatında rüzgar tüneli testinin standartlaşmasına neden olmuştur.

Tacoma Narrows Asma köprüsünün proje kusurları;

- Tabliye genişliği / açıklık oranı çok küçüktü. 11.9/853 = 1/72 (golden gate : 1/47 , boğaziçi köprüsü : 1/38)

- 2.44 m yüksekliğindeki boyuna I kesitli kirişler dolu gövde levhalardan oluşturulmuştu. Rüzgara direniyor, geçirmiyordu.

- Boyuna kiriş / açıklık oranı çok küçüktü. 2.44/853 = 1/350 (1/90 civari normal sayilir)

- Burulma rijitliği çok düşüktü.

- Kalıcı yükü çok azdı.

- Projede ön görülen hareketli yük olması gerekenin 1.5 katı dah azdı.

Tacoma Narrows asma köprüsünün olası göçme nedeni ;

- 7 kasim 1940, çok da kuvvetli esmeyen (yaklaşık 67 km/saat) rüzgarlı bir günde rezonansa gelerek yıkıldı. Projesine göre 140 km/saat rüzgara dayanıklı olmalıydı. Rüzgarın etkisiyle köprü önce 0.6 Hz frekansla 0.5 m yukarı-aşağı salınım yapmaya başladı. Ardından 0.2 Hz lik dönme (burulma) salınımı başladı. Salınım sırasında sol kenar sağ kenara nazaran 8.5 m yukarıda ve aşağıda yer alıyordu. Düzgün esen rüzgar sonucunda giderek şiddetlenen salınımların frekansı köprünün öz frekansı ile çakıştı, köprü çöktü. Rezonans nedeni ile göçme teorisi tartışmalıdır. Son yıllarda yapılan çalışmalar 0.2 Hz lik salınımın köprüyü rezonansa sokamayacağı yönündedir. Farklı göçme teorileride mevcuttur.

Tacoma Narrows Asma köprüsünün proje kusurları;

- Tabliye genişliği / açıklık oranı çok küçüktü. 11.9/853 = 1/72 (golden gate : 1/47 , boğaziçi köprüsü : 1/38)

- 2.44 m yüksekliğindeki boyuna I kesitli kirişler dolu gövde levhalardan oluşturulmuştu. Rüzgara direniyor, geçirmiyordu.

- Boyuna kiriş / açıklık oranı çok küçüktü. 2.44/853 = 1/350 (1/90 civari normal sayilir)

- Burulma rijitliği çok düşüktü.

- Kalıcı yükü çok azdı.

- Projede ön görülen hareketli yük olması gerekenin 1.5 katı dah azdı.

Tacoma Narrows asma köprüsünün olası göçme nedeni ;

- 7 kasim 1940, çok da kuvvetli esmeyen (yaklaşık 67 km/saat) rüzgarlı bir günde rezonansa gelerek yıkıldı. Projesine göre 140 km/saat rüzgara dayanıklı olmalıydı. Rüzgarın etkisiyle köprü önce 0.6 Hz frekansla 0.5 m yukarı-aşağı salınım yapmaya başladı. Ardından 0.2 Hz lik dönme (burulma) salınımı başladı. Salınım sırasında sol kenar sağ kenara nazaran 8.5 m yukarıda ve aşağıda yer alıyordu. Düzgün esen rüzgar sonucunda giderek şiddetlenen salınımların frekansı köprünün öz frekansı ile çakıştı, köprü çöktü. Rezonans nedeni ile göçme teorisi tartışmalıdır. Son yıllarda yapılan çalışmalar 0.2 Hz lik salınımın köprüyü rezonansa sokamayacağı yönündedir. Farklı göçme teorileride mevcuttur.

indirme linki - Tacoma Narrows Köprüsünün Göçme Nedenleri (Understanding Tacoma Narrows Bridge Collapse)

Florida Uluslararası Üniversitesi Yaya Köprüsünün Toptan Göçmesi (Pedestrian Bridge Collapse at Florida International University, Miami, FL)

15 Mart 2018 tarihinde yapım aşamasında toptan göçmesi gerçekleşen Miami, Florida Uluslararası Üniversitesi Yaya Köprüsünün İş Güvenliği ve Sağlığı İdaresi (Occupational Safety and Health Administration - OSHA) tarafından araştırma raporu Haziran 2019 tarihinde kamuoyu ile paylaşılmıştır.

Raporun tamamının indirme linki :

In June 2019, the U.S. Department of Labor, Occupational Safety and Health Administration (OSHA) released a report titled “Investigation of March 15, 2018 Pedestrian Bridge Collapse at Florida International University, Miami, FL”.

Below is its Executive Summary.

On March 15, 2018, at approximately 1:45 p.m., a pedestrian bridge under construction in Miami, Florida, collapsed. One employee and five motorists were fatally injured, and another employee permanently disabled, when the bridge fell as the motorists waited for the traffic light underneath the bridge and as the employees were performing work activities on top of the bridge structure. The bridge at the present stage of construction consisted of a single concrete truss spanning approximately 174 feet and weighing approximately 930 tons. It was placed over the piers just five days prior to the collapse. An adjoining span of concrete truss was to be constructed next over the canal to make a continuous bridge of 289 feet. The concrete bridge was cast at a nearby off-site location using what is known as Accelerated Bridge Construction (ABC) and then transported to its final location. ABC provides minimal traffic disruption. The bridge was financed through federal grants, and constructed at the campus of Florida International University (FIU) in Miami. The FIU project was a class A Local Agency Program (LAP) project. The bridge would connect the FIU campus with the City of Sweetwater where many FIU students reside.

The incident was extensively covered by live television and print media. The Occupational Safety and Health Administration (OSHA) sent officials from the agency’s Fort Lauderdale Area Office, and a forensic structural engineer from the OSHA Directorate of Construction, Office of Engineering Services (OES), in Washington, D.C., to determine the cause of the collapse and whether industry or OSHA standards were violated. During the first week of investigation, OSHA maintained a 24-hour surveillance at the incident site. OSHA worked closely with the National Transportation Safety Board (NTSB) and local officials, inspecting the remnants of the fallen bridge, and interviewing contractors to determine construction activities preceding the collapse.

OSHA conducted numerous interviews, reviewed pertinent construction documents and structural computations performed by the structural engineer of record (EOR), examined the failed pieces, conducted its own structural analysis, and viewed hundreds of photographs of the bridge taken before and after the collapse.

We thank the OSHA Fort Lauderdale Area Office, particularly Assistant Area Director Juan Torres, and Compliance Officer Anthony Campos, for their untiring effort and dedication. Alan Lu, Ph.D., PE, performed finite element analysis, and Bryan Ewing Ph.D., PE, performed hand computations, both of our office. We thank NTSB, and all the NTSB field staff for their steadfast co-operation during OSHA’s investigation.

As a result of the investigation, OES concludes that:

1. FIGG Bridge Engineers (FIGG), the Engineer of Record (EOR), failed to recognize that the bridge was in danger of collapsing when it inspected it hours before the collapse. The concrete truss had developed numerous wide and deep structural cracks jeopardizing the integrity of the bridge. The EOR should have immediately instructed that the bridge be shored at appropriate locations and SW 8th Street be closed. At the time of collapse, the post-tensioning bars were being re-tensioned at the specific instructions of the EOR.

2. The bridge had structural design deficiencies that contributed to the collapse during construction stage III. The cracks on the bridge occurred due to deficient structural design.

3. The morning of the incident, EOR held a meeting with project participants after evaluating the cracks over the course of the previous two days. At that meeting, the EOR acknowledged that his computations could not replicate the cracks and therefore, he did not know why the cracks were occurring. The Construction Engineer and Inspector (CEI) of the project advised the EOR at this meeting that the cracks were lengthening daily. Despite these admissions and the knowledge that the cracks were growing in size, EOR stated more than once that the cracks did not present any safety concerns.

4. The magnitude of the cracks warranted that SW 8th Street be immediately closed, and the concrete truss be shored and supported at multiple intermediate locations to reduce the loads in the north diagonal and the node until final evaluations were done and remedial measures implemented.

5. Networking Engineering Services, Inc. dba Bolton Perez and Associates, Inc. (BPA) was retained by FIU to be the CEI of the project. BPA failed to classify the cracks, which were structural in nature, in accordance with the Florida Department of Transportation (FDOT) requirements. BPA, as a CEI, was expected to exercise its own independent professional judgement in accordance with their contract with FIU and FDOT requirements. With intimate knowledge of extensive cracking on the bridge, BPA failed to recognize that the bridge was in danger of collapsing, and did not recommend to FIU, MCM or others to close the street and shore the bridge, regardless of the opinion held by the EOR.

6. Munilla Construction Management, Inc. (MCM), the design-build contractor, was aware that the cracks were “getting larger” as reported by MCM superintendent and quality control personnel on March 12 and 14, 2018. On March 13, 2018, EOR stated in an email to MCM, among the list of facts, that “since Saturday (March 10, 2018), MCM has been monitoring the cracks and they have not grown in size.” MCM should have immediately informed EOR on March 14, 2018, that this assumption was not valid. Despite this oversight on the part of MCM, EOR was provided with photographs and measurements of the cracks in the days leading up to the collapse and was specifically informed by BPA during the morning meeting on March 15, 2018, that the cracks were lengthening.

7. MCM, the design-build contractor, deferred to the decision of EOR and failed to exercise its own independent professional judgement, as a constructor of the bridge, to close the traffic on SW 8th Street until the cause of the cracks were conclusively determined by EOR and peer reviewed. MCM had extensive construction experience in concrete structures and had intimate knowledge of the magnitude of cracks, which were growing in size daily. MCM’s deference to EOR in light of the conclusion No. 6 above, and failure to exercise their own independent judgment with regard to implementing necessary safety measures were unreasonable.

8. The evaluations of the cracks by EOR, and his recommendation to re-tension the post-tensioning bars of diagonal 11, were not included in the original design and therefore should have been subject to peer review.

9. The consultant retained by EOR to conduct independent peer review of the EOR’s design, as per FDOT requirements, did not check the structural integrity of the bridge under different construction stages, a violation of the FDOT requirements. The independent check was performed only under the final design stage when all segments of the bridge were constructed and completed.

10. EOR failed to provide construction documents to Louis Berger at 30%, 60% and 90% of completion of construction documents, in accordance with the FDOT requirements.

11. EOR should have known that the consultant who conducted the peer review did not check the structural design of the truss design at stage III, as required by FDOT, meriting extra safety precautions by EOR.

12. EOR should have known that the truss was a non-redundant structure and if one diagonal member failed, the entire bridge could collapse. Given the nature and extent of the cracking and the non-redundancy of the bridge design, necessary safety precautions should have included closing the roadway below the bridge and immediately providing shoring to the bridge at suitable locations until a complete evaluation was done.